- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

6.75x19.5

SPW/FINEST/ LuTong/GKZG

GKTS195675

| Availability: | |

|---|---|

| Quantity: | |

Matched tire size: 9R19.5

Matched tire size: 9R19.5

Product name: Aluminum wheel

Size: 19.5*6.75

Material: Aluminum 6061

Surface treatment: Machine/Single polish/Double polish

Load Capacity: 2750KGS

MOQ and Leadtime: 50PCS / 25 days

Warranty Period: 5 Years

Type: Truck Accessories

Place of Origin: Shandong, China (Mainland)

Brand:SPW/GKZG/FINEST/POLARIS

OEM: Support (OEM for BYD, YUTONG, DONGFENG, SHAC MAN etc.)

Certificate: IATF16949, INMETRO, EAC, DOT

If you need, Gongka Heavy Industry Machinery (Shandong) Co., Ltd;

Can provide customization on vent hole, packaging and logo.

| PART NO. | RIM | OFFSET | BOLT HOLE | P.C.D (MM) | C.B.D (MM) | LOAD CAPACITY (KG) | EQUIPPED WITHTYRE | ||

| NO. | DIA | ||||||||

| GKTS195675 | C01 | 19.5*6.75 | 148 | 5 | 29 | 203.2 | 146 | 2750 | 9R19.5 225/70R19.5 |

| C02 | 148 | 6 | 32 | 222.25 | 163 | ||||

| C03 | 148 | 10 | 26 | 225 | 176 | ||||

| C04 | 148 | 8 | 26 | 275 | 214/221 | ||||

| C05 | 148 | 6 | 21 | 205 | 161 | ||||

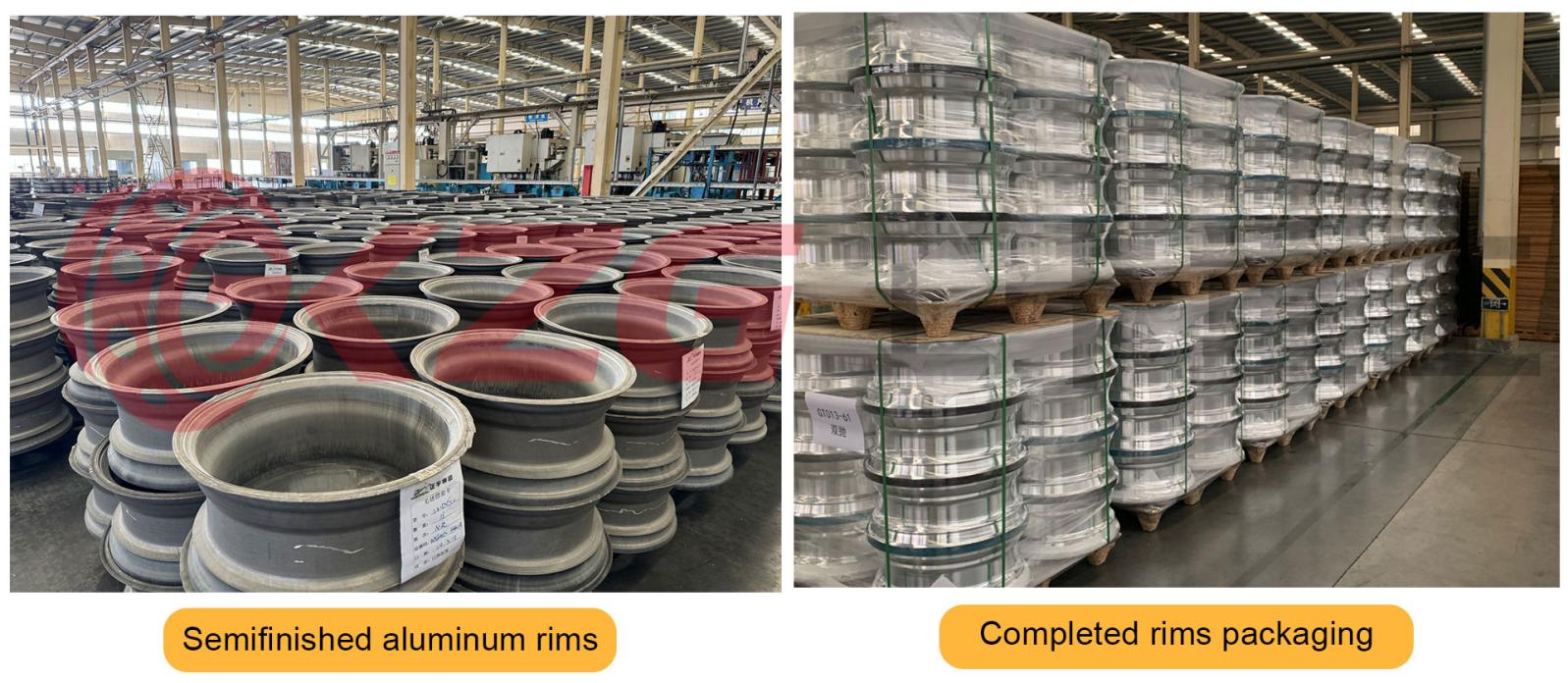

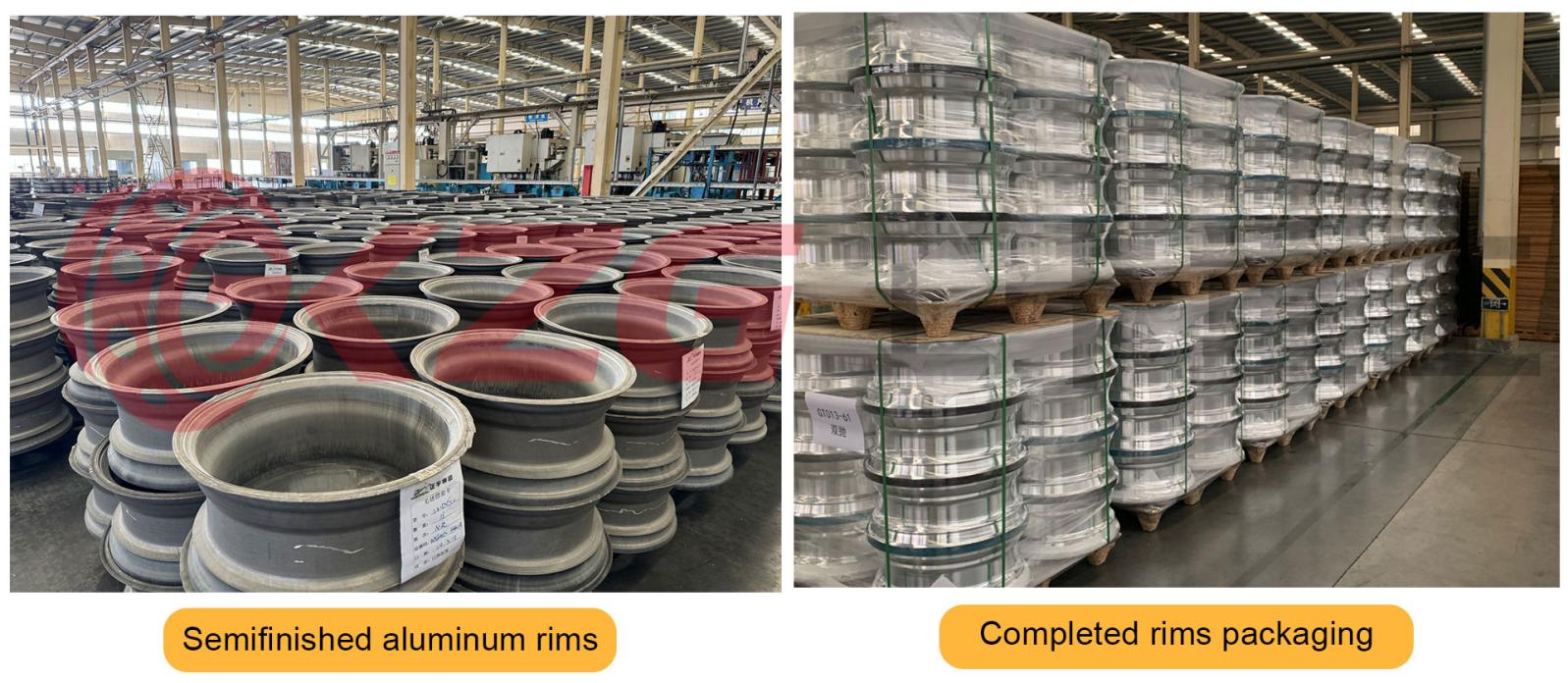

Three package types can be chosen, including pallet type, carton type, non-woven package, as below. And also can be negotiated.

Assembled tire and wheel can be arranged as well!

Gongka Heavy Industry Machinery (Shandong)Co.,Ltd was established in 2019, located in Xishui Industrial Park, Guangrao County, Dongying City. It belong to Zhengyu Wheel Group; The company covers an area of 150000 square meters, is an enterprise specializing in steel wheel manufacturing and integrating independent research and development, design, manufacture, sales and international trade.

The company maintains several core production technology, has the self-managerial import & export authority. "Donglun", "Dunchi " and other several famous brands have been recognized by the domestic well-known automobile manufacturers, and also are exported to Europe and the United States, Japan, Korea, southeast Asia, the Middle East, Africa and so on more than 30 countries and regions.

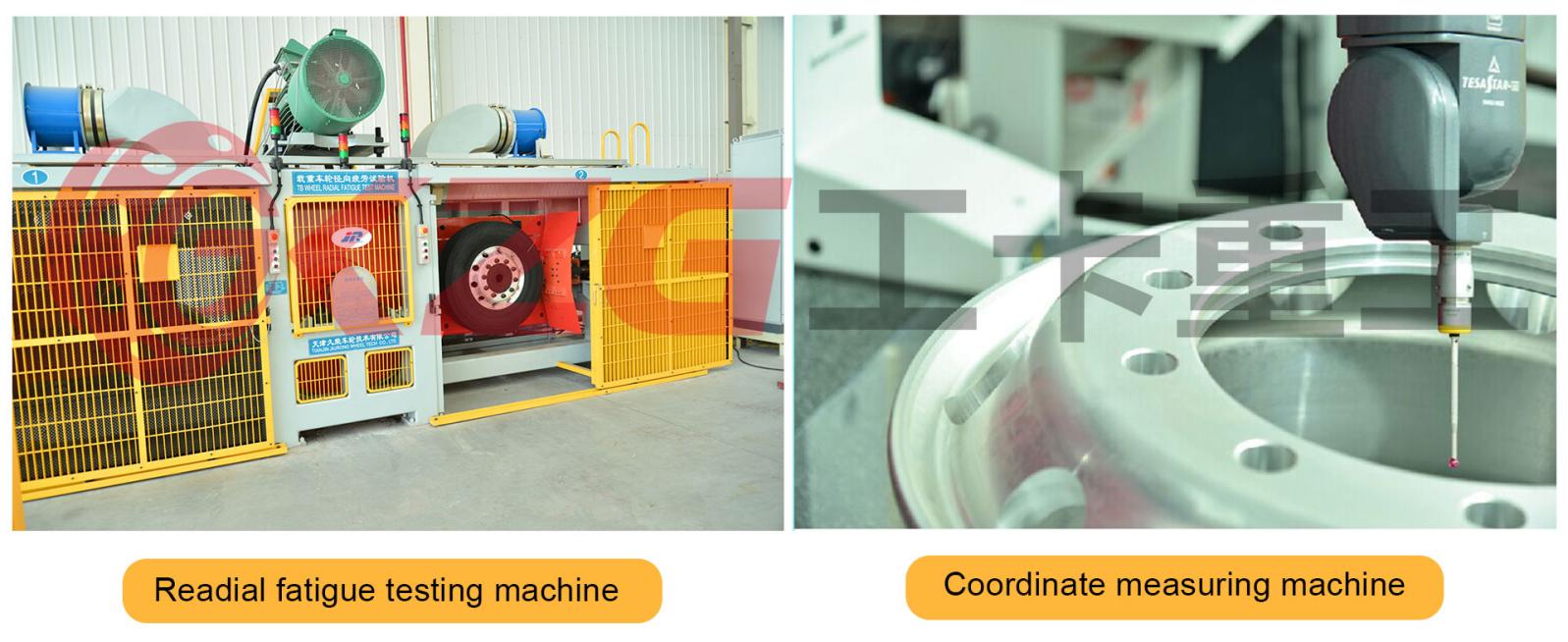

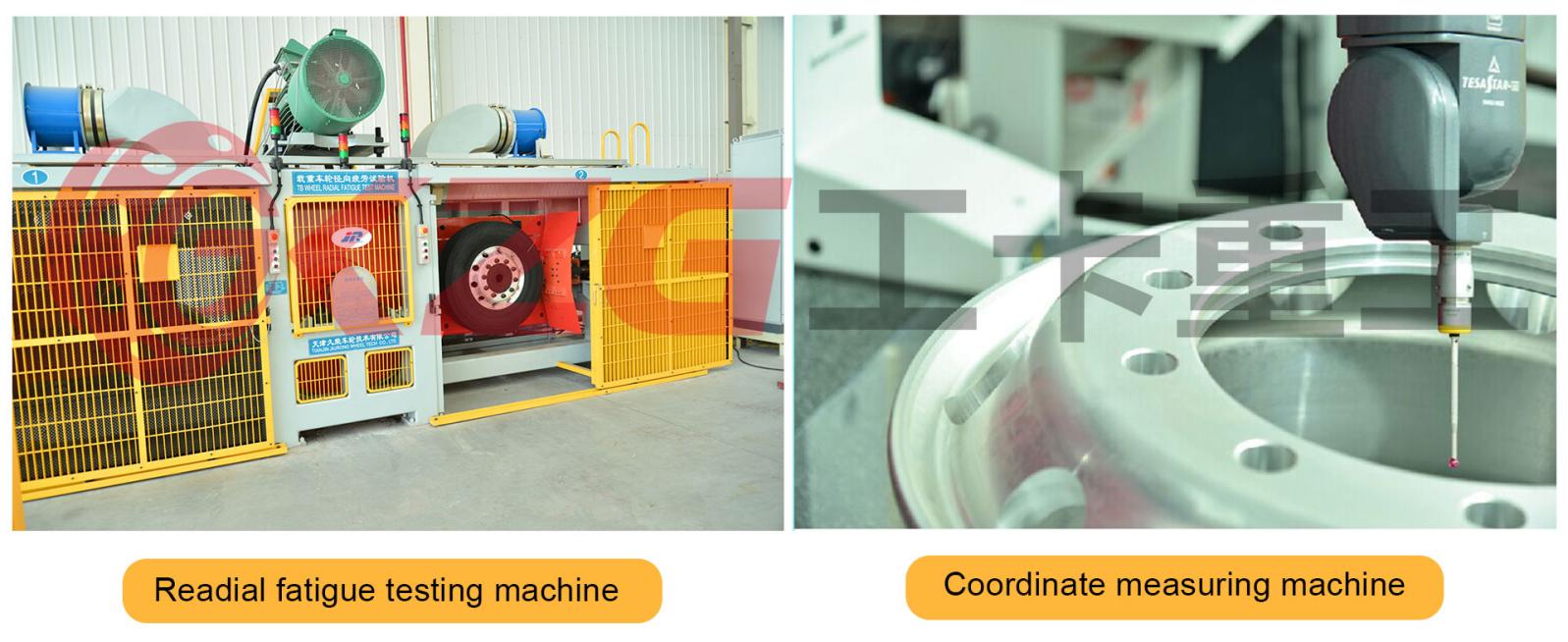

The company has introduced the world’s most advanced production technology of forged of aluminum magnesium alloy wheel. and all the equipment are purchased from the international first class industry manufacturers: The CNC spinning machine of Germany LEIFELD and SBS company, the CNC machining center of Italy IMT, and the polishing machine of Spain AUTOPULIT company, and the robot of Switzerland ABB company, as well as the automatic detection equipment of BII company of the United States, and has introduced 5 high automation production line, equipped with more than 120 sets of advanced equipment, the robot is more than 50 units, the annual output is 3 million pieces.

Compared with regular steel wheel with inner tube, the weight aluminum magnesium alloy rim of GKZG is reduced nearly 50%.

Compared with regular steel wheel with inner tube,the weight aluminum magnesium alloy rim of GKZG is reduced 25kg each set.

Compared with the pressure needed to make the wheels happening 5cm deformation Aluminum magnesium alloy rim of GKZG-71200kg Regular steel wheel-13600kg.

The heat conduction coefficient pf the aluminum magnesium alloy is 3 times of steel, addition,the structural feature of the aluminum and magnesium alloy wheel is easily disperse the heat generated from the tire and base plate to the air.

(1) Make the car keeping the proper temperature to lower the rate of puncture

(2) Obviously prolong the service mileage of tire

(3) Greatly reduce the maintenance cost of the braking systems

The wheel of forged aluminum magnesium alloy wheel of GKZG is an integral forming.The surface is smooth and is handled easily.The surface has aluminum alloy metal texture. The polishing technology makes products having noble style and quality.

The aluminum magnesium alloy wheel of GKZG is forged by an integral forming. The roundness is less than 0.1 mm,but the roundness error of steel wheels of is in more than 1 mm; When it is full load: The average deformation volume of the forged

aluminum magnesium alloy wheel of GKZG is 0.52 mm, but the average deformation volume of steel wheel is 2.24mm. The rolling resistance of the forged aluminum magnesium alloy wheel of GKZG is small, and tire wear is also uniform, and the driving is more smooth and safe.

It is assumed that a car driving 300000 km, the consumed diesel oil is 126000 liters.After using the forged aluminum magnesium alloy wheel of GKZG, the oil consumption of the vehicle can be saved 6300 liters a year, that is the fuel consumption of the vehicle is saved 41139 Yuan, and the tire cost of vehicle is saved 9900 Yuan, and the additional income of more carrying cargo is 14400 Yuan, and the total saving for a single car is 65439 Yuan.

Note: The tire life is extended life by 15%, and tire life is fixed for the time being is 200000 kilometers.

(the specific data shall be based on the actual measurement)

Under the normal situation, when the car reduces every 100kg in weight, the CO2 emissions can be reduced 5g/km; and when the car reduces every 10% in weight, the fuel consumption can be reduced by 6%-8%. The lightweight design has become an urgent need to reduce the emissions of the transportation vehicle.

Precision work and intelligent manufacturing, creating bright future

Civilization, integrity, justice, innovation

To be the world-class high-end wheel manufacturer

To provide safer,greener and more economic wheel solution,to dedicate to the green life

No benefit if no everything, and no everything if no benefit

People oriented,sustainable development,achieving self by benefiting others, win-win cooperation

Sense of quality, sense of science and technology, sense of value

The sustainable and healthy development of enterprises is inseparable from business civilization. Every employee of Gongka Heavy Industry Machinery (Shandong) Co., Ltd. is well aware of the importance of win-win cooperation and is committed to providing the best service to every customer. As an enterprise at the forefront of the times, Gongka Heavy Industry Machinery (Shandong) Co., Ltd. updates equipment production technology according to market demand and advances with the times. In order to better meet the requirements of the market.

The sustainable and healthy development of enterprises is inseparable from business civilization. Every employee of Gongka Heavy Industry Machinery (Shandong) Co., Ltd. is well aware of the importance of win-win cooperation and is committed to providing the best service to every customer. As an enterprise at the forefront of the times, Gongka Heavy Industry Machinery (Shandong) Co., Ltd. updates equipment production technology according to market demand and advances with the times. In order to better meet the requirements of the market.

GONGKA HEAVY INDUSTRY MACHINERY (SHANDONG) CO.,LTD.

LOOKING FORWARD TO ESTABLISH BUSINESS RELATIONSHIP WITH YOUR COMPANY IN THE FUTURE.

Matched tire size: 9R19.5

Matched tire size: 9R19.5

Product name: Aluminum wheel

Size: 19.5*6.75

Material: Aluminum 6061

Surface treatment: Machine/Single polish/Double polish

Load Capacity: 2750KGS

MOQ and Leadtime: 50PCS / 25 days

Warranty Period: 5 Years

Type: Truck Accessories

Place of Origin: Shandong, China (Mainland)

Brand:SPW/GKZG/FINEST/POLARIS

OEM: Support (OEM for BYD, YUTONG, DONGFENG, SHAC MAN etc.)

Certificate: IATF16949, INMETRO, EAC, DOT

If you need, Gongka Heavy Industry Machinery (Shandong) Co., Ltd;

Can provide customization on vent hole, packaging and logo.

| PART NO. | RIM | OFFSET | BOLT HOLE | P.C.D (MM) | C.B.D (MM) | LOAD CAPACITY (KG) | EQUIPPED WITHTYRE | ||

| NO. | DIA | ||||||||

| GKTS195675 | C01 | 19.5*6.75 | 148 | 5 | 29 | 203.2 | 146 | 2750 | 9R19.5 225/70R19.5 |

| C02 | 148 | 6 | 32 | 222.25 | 163 | ||||

| C03 | 148 | 10 | 26 | 225 | 176 | ||||

| C04 | 148 | 8 | 26 | 275 | 214/221 | ||||

| C05 | 148 | 6 | 21 | 205 | 161 | ||||

Three package types can be chosen, including pallet type, carton type, non-woven package, as below. And also can be negotiated.

Assembled tire and wheel can be arranged as well!

Gongka Heavy Industry Machinery (Shandong)Co.,Ltd was established in 2019, located in Xishui Industrial Park, Guangrao County, Dongying City. It belong to Zhengyu Wheel Group; The company covers an area of 150000 square meters, is an enterprise specializing in steel wheel manufacturing and integrating independent research and development, design, manufacture, sales and international trade.

The company maintains several core production technology, has the self-managerial import & export authority. "Donglun", "Dunchi " and other several famous brands have been recognized by the domestic well-known automobile manufacturers, and also are exported to Europe and the United States, Japan, Korea, southeast Asia, the Middle East, Africa and so on more than 30 countries and regions.

The company has introduced the world’s most advanced production technology of forged of aluminum magnesium alloy wheel. and all the equipment are purchased from the international first class industry manufacturers: The CNC spinning machine of Germany LEIFELD and SBS company, the CNC machining center of Italy IMT, and the polishing machine of Spain AUTOPULIT company, and the robot of Switzerland ABB company, as well as the automatic detection equipment of BII company of the United States, and has introduced 5 high automation production line, equipped with more than 120 sets of advanced equipment, the robot is more than 50 units, the annual output is 3 million pieces.

Compared with regular steel wheel with inner tube, the weight aluminum magnesium alloy rim of GKZG is reduced nearly 50%.

Compared with regular steel wheel with inner tube,the weight aluminum magnesium alloy rim of GKZG is reduced 25kg each set.

Compared with the pressure needed to make the wheels happening 5cm deformation Aluminum magnesium alloy rim of GKZG-71200kg Regular steel wheel-13600kg.

The heat conduction coefficient pf the aluminum magnesium alloy is 3 times of steel, addition,the structural feature of the aluminum and magnesium alloy wheel is easily disperse the heat generated from the tire and base plate to the air.

(1) Make the car keeping the proper temperature to lower the rate of puncture

(2) Obviously prolong the service mileage of tire

(3) Greatly reduce the maintenance cost of the braking systems

The wheel of forged aluminum magnesium alloy wheel of GKZG is an integral forming.The surface is smooth and is handled easily.The surface has aluminum alloy metal texture. The polishing technology makes products having noble style and quality.

The aluminum magnesium alloy wheel of GKZG is forged by an integral forming. The roundness is less than 0.1 mm,but the roundness error of steel wheels of is in more than 1 mm; When it is full load: The average deformation volume of the forged

aluminum magnesium alloy wheel of GKZG is 0.52 mm, but the average deformation volume of steel wheel is 2.24mm. The rolling resistance of the forged aluminum magnesium alloy wheel of GKZG is small, and tire wear is also uniform, and the driving is more smooth and safe.

It is assumed that a car driving 300000 km, the consumed diesel oil is 126000 liters.After using the forged aluminum magnesium alloy wheel of GKZG, the oil consumption of the vehicle can be saved 6300 liters a year, that is the fuel consumption of the vehicle is saved 41139 Yuan, and the tire cost of vehicle is saved 9900 Yuan, and the additional income of more carrying cargo is 14400 Yuan, and the total saving for a single car is 65439 Yuan.

Note: The tire life is extended life by 15%, and tire life is fixed for the time being is 200000 kilometers.

(the specific data shall be based on the actual measurement)

Under the normal situation, when the car reduces every 100kg in weight, the CO2 emissions can be reduced 5g/km; and when the car reduces every 10% in weight, the fuel consumption can be reduced by 6%-8%. The lightweight design has become an urgent need to reduce the emissions of the transportation vehicle.

Precision work and intelligent manufacturing, creating bright future

Civilization, integrity, justice, innovation

To be the world-class high-end wheel manufacturer

To provide safer,greener and more economic wheel solution,to dedicate to the green life

No benefit if no everything, and no everything if no benefit

People oriented,sustainable development,achieving self by benefiting others, win-win cooperation

Sense of quality, sense of science and technology, sense of value

The sustainable and healthy development of enterprises is inseparable from business civilization. Every employee of Gongka Heavy Industry Machinery (Shandong) Co., Ltd. is well aware of the importance of win-win cooperation and is committed to providing the best service to every customer. As an enterprise at the forefront of the times, Gongka Heavy Industry Machinery (Shandong) Co., Ltd. updates equipment production technology according to market demand and advances with the times. In order to better meet the requirements of the market.

The sustainable and healthy development of enterprises is inseparable from business civilization. Every employee of Gongka Heavy Industry Machinery (Shandong) Co., Ltd. is well aware of the importance of win-win cooperation and is committed to providing the best service to every customer. As an enterprise at the forefront of the times, Gongka Heavy Industry Machinery (Shandong) Co., Ltd. updates equipment production technology according to market demand and advances with the times. In order to better meet the requirements of the market.

GONGKA HEAVY INDUSTRY MACHINERY (SHANDONG) CO.,LTD.

LOOKING FORWARD TO ESTABLISH BUSINESS RELATIONSHIP WITH YOUR COMPANY IN THE FUTURE.